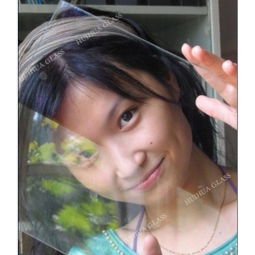

Are you looking to enhance the clarity and brightness of your glass or screen? Look no further than AR coating. This innovative technology has revolutionized various industries, from automotive to solar energy. In this article, we will delve into the intricacies of AR coating, exploring its benefits, applications, and the science behind it.

Understanding AR Coating

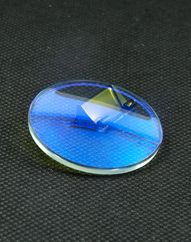

AR coating, short for anti-reflection coating, is designed to improve the transmittance of glass or screens while reducing their reflectivity. By doing so, it enhances the overall visual experience and energy efficiency of the device. The coating is typically made up of multiple layers of materials with varying refractive indices, which work together to minimize reflections and maximize light transmission.

One of the key principles behind AR coating is the concept of destructive interference. When light passes from a low refractive index material to a high refractive index material, it experiences a phase shift. This phase shift causes the reflected light to be out of phase with the incident light, resulting in the cancellation of the reflected waves. This phenomenon is known as destructive interference, and it effectively reduces the amount of light that is reflected off the surface.

Applications of AR Coating

AR coating finds its applications in a wide range of industries. Here are some of the most notable ones:

| Industry | Application |

|---|---|

| Automotive | Windshields and rear windows of cars to improve visibility and reduce glare |

| Solar Energy | Photovoltaic glass to increase the efficiency of solar panels |

| Consumer Electronics | Smartphone and tablet screens to enhance image clarity and reduce reflections |

| Advertising | Outdoor billboards to improve visibility and reduce glare |

AR coating is also used in various other applications, such as camera lenses, optical instruments, and architectural glass. Its ability to reduce reflections and improve light transmission makes it an invaluable addition to these products.

AR Coating Process

The process of applying AR coating involves several steps, each crucial to the final outcome. Here’s a brief overview of the process:

-

Cleaning: The surface to be coated must be thoroughly cleaned to remove any contaminants or impurities that could affect the adhesion of the coating.

-

Drying: After cleaning, the surface must be dried to ensure that no moisture is present, as it can interfere with the coating process.

-

Deposition: The coating material is deposited onto the surface using techniques such as vacuum evaporation or sputtering. The choice of technique depends on the specific requirements of the application.

-

Curing: Once the coating is applied, it must be cured to ensure that it adheres properly to the surface and achieves the desired properties.

-

High-Temperature Annealing: In some cases, high-temperature annealing is performed to improve the durability and performance of the coating.

The quality of the AR coating depends on the precision and consistency of each step in the process. Proper cleaning, drying, and deposition techniques are essential to ensure that the coating is effective and long-lasting.

Benefits of AR Coating

AR coating offers several benefits, making it a valuable addition to various products:

-

Increased Transmittance: AR coating significantly improves the transmittance of glass or screens, allowing more light to pass through and enhancing the visual experience.

-

Reduced Reflections: By minimizing reflections, AR coating improves the clarity and brightness of images, making them more enjoyable to view.

-

Improved Energy Efficiency: In applications such as solar energy, AR coating helps to increase the efficiency of the device by allowing more light to reach the intended surface.

-

Longevity: AR coating is designed to be durable and long-lasting, with many coatings offering a lifespan of up to 25 years.

These benefits make AR coating an attractive option for a wide range of applications, from consumer electronics to architectural glass.